Food Conveyor Belt Maintenance knowledge

Conveyor belt is an important part of the conveyor, which accounts for more than half of the total conveyor cost, so the assembly line in the daily operation of the conveyor belt how to maintain is particularly important, today we must give you a very analysis Common conveyor belt maintenance, it is nylon conveyor belt.

Nylon conveyor belt maintenance and repair are the following points:

1, the feeding direction should be along the running direction of the tape, in order to reduce the impact of the material when the tape should be taken chute, reducing the material falling distance; tape receiving section should shorten the distance between the roller and the use of buffer roller leakage, Conformity with soft moderation board, so as not to over-material board, scratch the belt conveyor belt.

2, different types, specifications, the number of layers of the conveyor belt should not be used together, the connector is best to use adhesive method.

3, Conveyor belt speed generally should not be more than 2.5 m / s, large block size, large abrasive material and the use of fixed petrol unloading device should try to use low speed.

4, the conveyor belt should pay attention to the following matters in use: ① avoid the roller is covered by the material, resulting in swirling ineffective, to prevent the leakage card stuck between the roller and the tape, pay attention to the lubrication of the active part, but not oily conveyor belt; With the load to start; ③ tape deviation occurs, when applied to take measures to correct; ④ found that the local damage when the tape made of cotton repair, so as to avoid expansion;

5, Conveyor drum diameter and the relationship between the conveyor belt layer, drive roller, the drum to the supporting and supporting roller groove angle requirements should be based on the design of transport aircraft, a reasonable choice.

6, the type of conveyor belt, structure, specifications, layers should be based on the conditions of use reasonable selection.

7, when storing the warehouse temperature should be maintained between 18-40 ℃, the relative humidity should be maintained at 50-80%.

8, during storage, the product must be placed in rolls, shall not be folded, during the placement should be flipped quarterly.

9, Conveyor belt should be kept clean during transportation and storage, avoid direct sunlight or rain and snow leaching, prevent contact with acids, alkalis, oils, organic solvents and other substances, and should be one meter away from the heating device.

To transport equipment to carry out long-life operations without accidents, the importance of routine maintenance and repair of all parts of the attention, the only way to play its efficient operation.

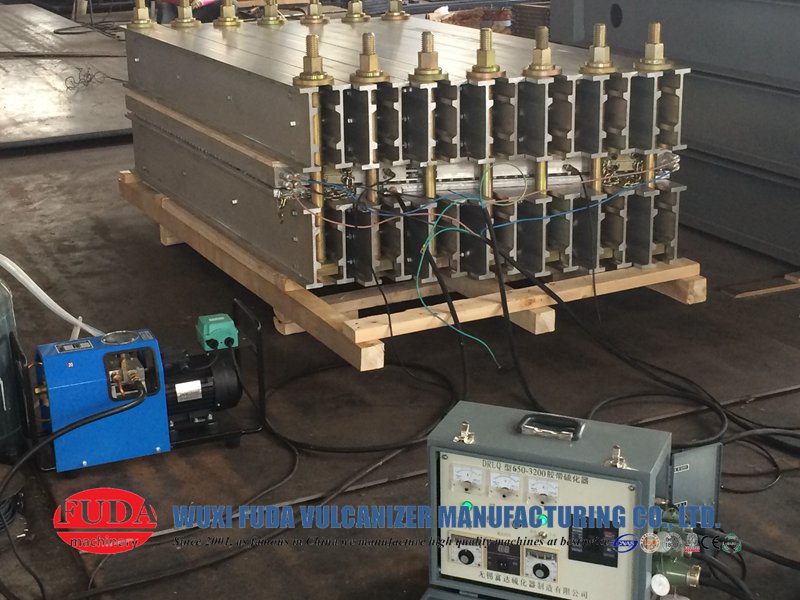

Conveyor belt is the core of the belt conveyor machine, no matter how good the belt conveyor, if the conveyor belt connection is not good, and the conveyor belt damage, will seriously affect the customer experience. Wuxi Fuda Vulcanizer Manufacturing Co., Ltd. specializing in the production of conveyor joints and repair vulcanizing machine, with more than 20 years of production experience, the products throughout the country’s major mining companies and overseas. And get the praise from all the clients.

For conveyor belt joints and repair equipment, please find Wuxi Fuda Vulcanizer Manufacturing Co., Ltd.

Address: Guangming industrial zone, Xibei town, Wuxi city, Jiangsu Province, China 214194

Mobile & WhatsApp: 86-15995216108 Skype: live:alex-fudamachine

Email: alexmachine@yeah.net & alex-fudamachine@hotmail.com

Website: wuxifuda.en.alibaba.com & www.conveyorbeltvulcanizer.com